Scan wechat for consultation

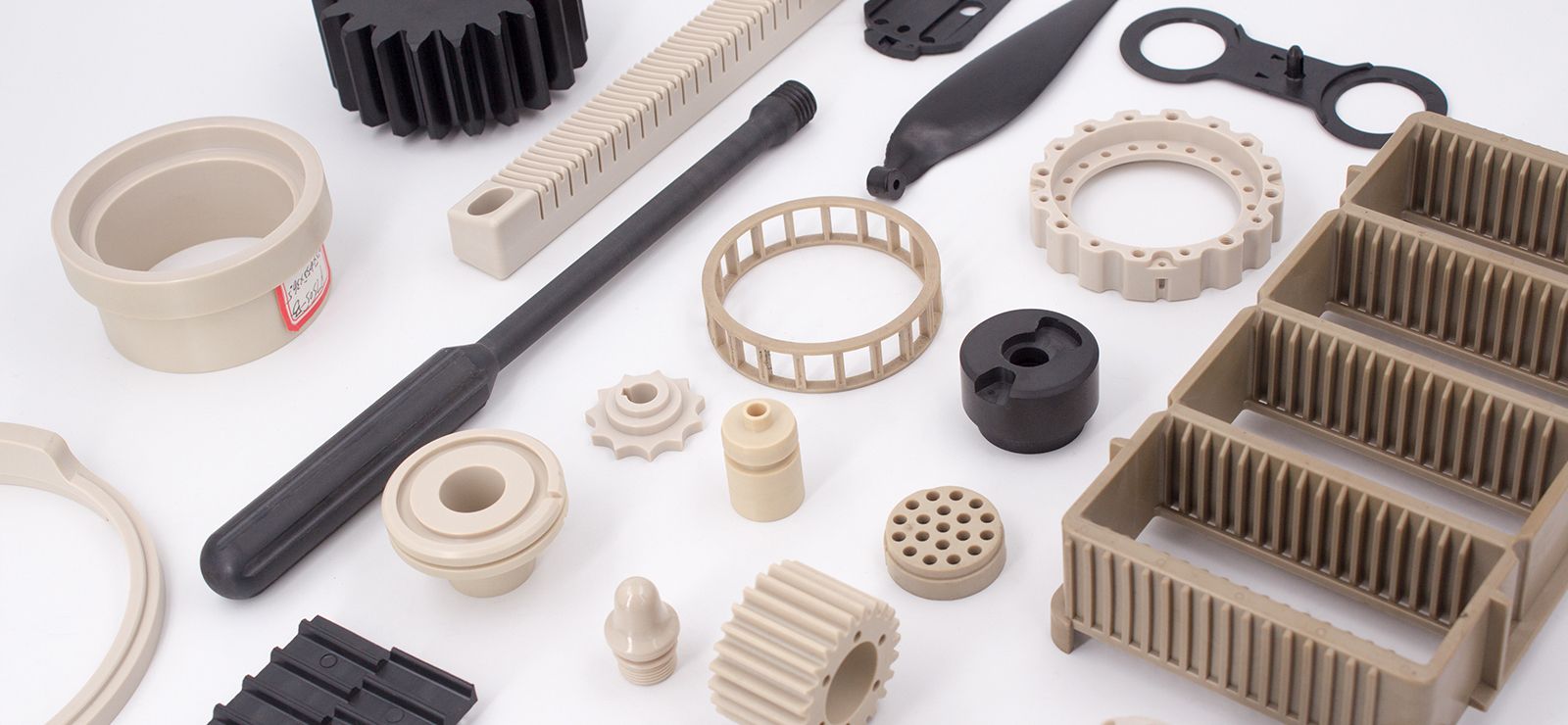

I. Введение в материал Полиэфирэфиркетон (PEEK) — высокотехнологичный термопластичный полимер с исключительными механическими свойствами, термостойкостью и химической стабильностью. Однако базовый PEEK является диэлектриком, что ограничивает его применение в электронике. Добавление проводящих наполнителей (углеродные волокна, нанотрубки, металлические порошки) позволяет создавать электропроводящие композиты PEEK, сохраняющие преимущества исходного материала с добавлением контролируемой электропроводности.

I. Einführung in leitfähiges PEEK-Material Polyetheretherketon (PEEK) ist ein Hochleistungsthermoplast mit hervorragenden mechanischen Eigenschaften, Hitzebeständigkeit und chemischer Stabilität. Reines PEEK ist jedoch elektrisch isolierend, was seine Anwendung in bestimmten elektronischen Bereichen einschränkt. Durch Zugabe leitfähiger Füllstoffe wie Kohlenstofffasern, Kohlenstoffnanoröhren oder Metallpulver entstehen leitfähige PEEK-Verbundwerkstoffe. Diese Materialien behalten die Vorteile von PEEK bei und bieten gleichzeitig stabile elektrische Leitfähigkeit, was ihren Einsatz in der Elektronikbranche erweitert.

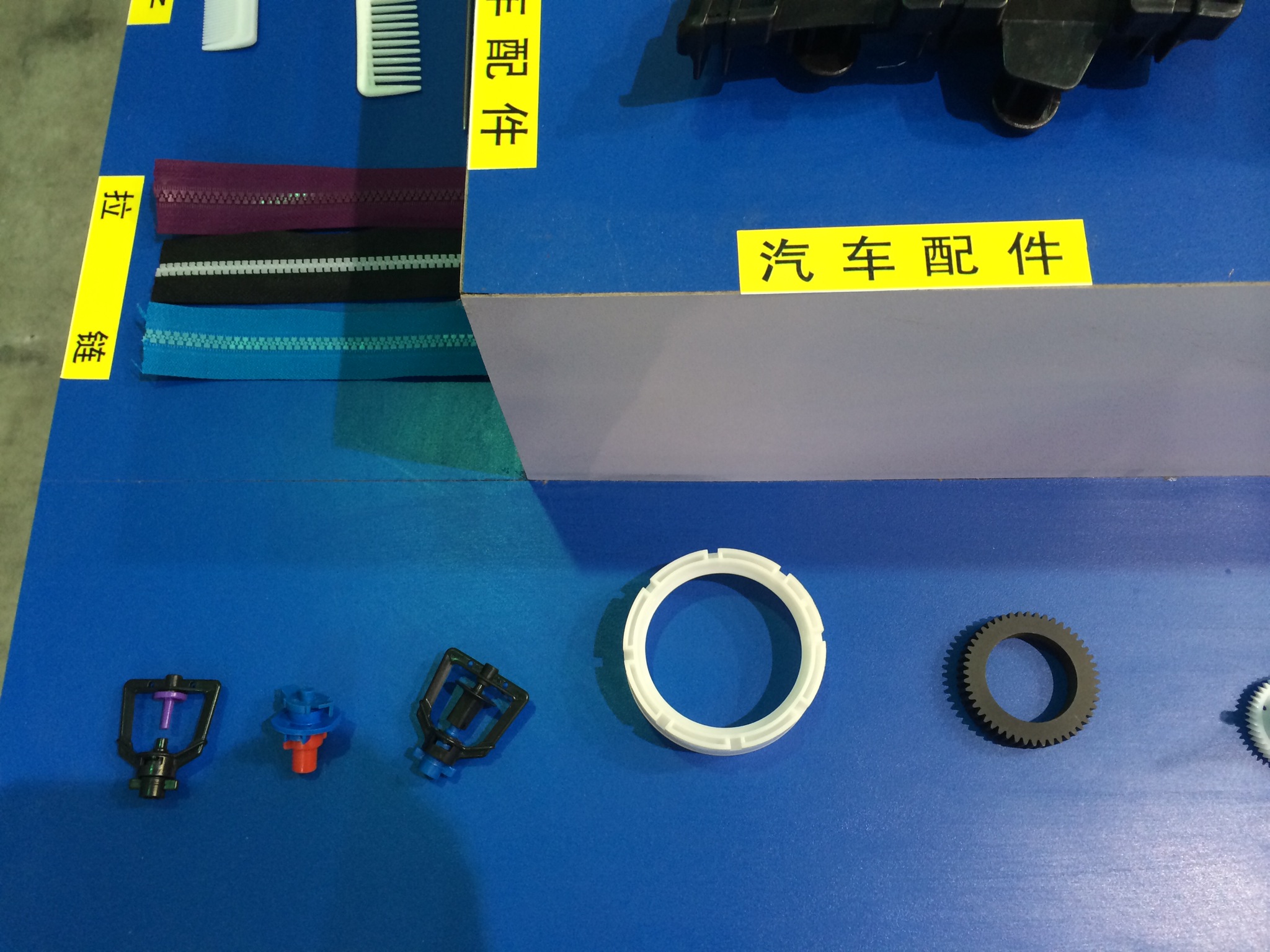

PEEK材料应用

Kynar Flex® 2800-20 Kynar Flex® 2801-00 Kynar Flex® 2821-00 Kynar Flex® 2850 PC Kynar Flex® 2850 WR Kynar Flex® 2850-00 Kynar Flex® 2850-02 Kynar Flex® 2850-04 Kynar Flex® 2850-07 Kynar Flex® 2900-04 Kynar Flex® 2950-05 Kynar Flex® 3030-10 Kynar Flex® 3030-15 Kynar Flex® 3030-50 Kynar Flex® 3120-10 Kynar Flex® 3120-15 Kynar Flex® 3120-50

VESTAKEEP® PEEK - NEXT GENERATION medical MATERIAL with strong features High performance for various medical application areas Four VESTAKEEP® PEEK grades for best performance in medical implants, dental applications and medical equipment

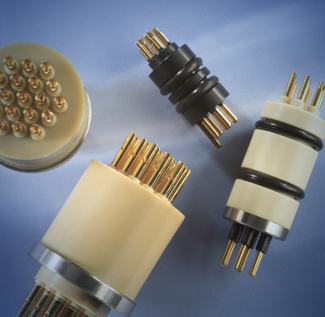

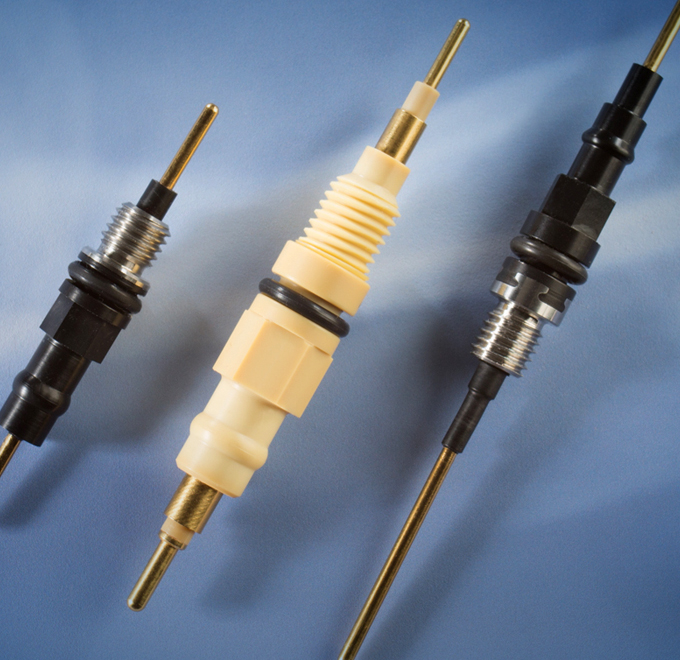

1. High-temperature Performance • Long-term use temperature: 260°C (short-term 300°C), UL94 V-0 flame retardant. • Heat deflection temperature (HDT): Pure resin 160°C (1.8MPa), Glass fiber reinforced 315°C. 3. Chemical Stability • Resistant media: Hydraulic oil (Skydrol 500B), Concentrated sulfuric acid (20°C), Seawater. • Limited media: Concentrated nitric acid (>50%), Molten alkali metals (HT™ modification required). 1. Aerospace • Components: Engine sealing rings, Bearing cages. • Benefits: Weight reduction of 50%, Resistant to aviation fuel, FAA/EASA certified. 2. Medical Equipment • Application: Spinal fusion cage (PEEK OPTIMA® LT1). • Advantages: X-ray transparency, Elastic modulus matching bone, Reduced stress shielding. 3. Electrical and Electronic • Application: 5G base station high-frequency connectors (APTIV™ film). • Advantages: Dielectric loss 0.001@10GHz, Resistant to reflow soldering (260°C). 4. Energy Industry • Application: Deep-sea valve seat (PEEK 150CA30). • Benefits: Service life extended from 6 months to 5 years, Maintenance cost reduced by 70%.